ENERGY EFFICIENT

For Maximum Energy Efficiency, Water is the Natural Choice

THE HIGHEST POSSIBLE SYSTEM EFFICIENCY

| Save 30 percent or more on HVAC energy consumption | |

| Multiple variable speed components work in unison | |

| Water is naturally a high-efficiency medium for energy transfer | |

| Water requires the least horsepower to deliver heat or AC | |

| Systems custom designed to building and climate requirements |

When it comes to minimizing a building’s energy expenses, water always wins. And it does so without compromising safety, comfort or equipment lifecycle. Even the most basic hydronic systems will consistently outperform VRF (variable refrigerant flow) systems by 30 to 40 percent. In other words, hydronics use 30 to 40 percent less energy. This is due to being water-cooled, minimizing the effect of outdoor air, and having higher compressor efficiency in factory sealed refrigerant circuits versus field piping, which reduces system pump horsepower.

With the integration of “green” components, such as geothermal heat pumps, energy recovery or sharing, or solar thermal collectors, hydronic system performance provides an even larger gain in efficiency.

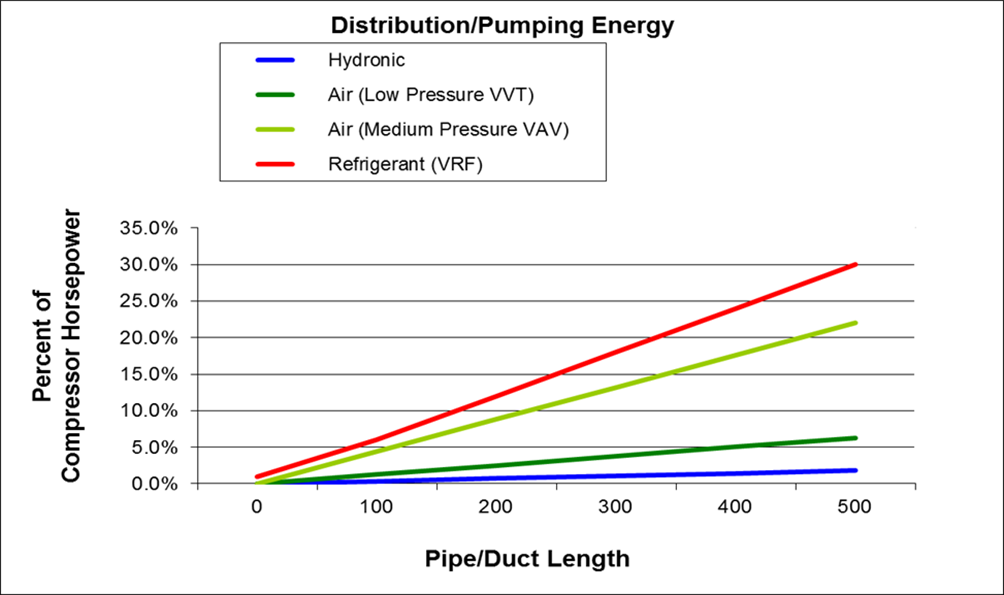

One key to a hydronic system’s outstanding efficiency is its ability to transfer heat at a cost substantially lower than other technologies, including VRF and central air systems. The chart below compares the energy used by various systems to distribute heating or cooling capacity throughout a building.

The curves indicate that as the distance increases, so does the cost to provide heating or cooling capacity. Energy is moved around the building in pipe (hydronic), duct (forced air system), or refrigerant lines (VRF).

Water takes a landslide victory here because of three main factors:

- Its load-carrying capacity (specific heat) is very high.

- Modern circulators used in a hydronic system are more energy efficient than fans (air system) or compressors (VRF).

- The transportation of energy in water does not affect the efficiency of the chiller or heat pump, in the way that moving refrigerant affects the efficiency of the compressor in a VRF system.

Inside VRF

Fact: Many VRF systems are conservatively measured at 50 percent below published energy efficiencies. The reason is simple: VRF published ratings are intended to compare equipment against other VRF manufacturers. A real building requires multiple de-rates to the rated efficiency based on actual operation. These include:

Outdoor air temperature, length of refrigerant lines, elevation change between the condensing unit and indoor split units, and multiple real world operating differences from prescribed laboratory test points. The most common differences from laboratory tests are indoor room temperature when cycling, actual airflow, and constant versus variable room loads. Even oil migration in the refrigerant charge effects efficiency as applied.

When VRF systems are lab tested to find published IEER (Integrated Energy Efficiency Rating), a 12.5 foot separation between the indoor and outdoor unit is used. In a building, there’s likely to be hundreds of feet of copper refrigerant line installed. And we know that for refrigerant, distance is the number one energy hog.

Variable? Water does that…

Proponents of VRF systems are quick to mention the use of variable speed compressors. And yes, under partial-load conditions, that’s a benefit. What is rarely discussed is that any given hydronic system is likely to use numerous “variable” components; a variable-speed pump, chiller, fan coil and a modulating boiler. In effect, these items compound their energy efficiency.

And if that’s not enough, variable water temperature is an even bigger benefit. The ability to alter water temperatures based on outdoor air temperature, room setpoint and type of equipment installed is a huge benefit that only hydronic systems can provide.

Monster Trucks and Race Cars

A monster truck and a NASCAR stock racer have similar horsepower ratings. Suffice it to say, they’re built for very different purposes, and neither would excel in the other’s arena.

Unlike a VRF system, which is simply sized for part of a building, a hydronic system is adaptable and can be custom tailored to the specific needs of your complete facility and climate; not just heating or cooling but the complete energy consumption profile.

Take, for example, an office building in Houston and a similar facility in Minneapolis. The two have vastly different HVAC requirements. In the case of a VRF installation, both would receive the exact same equipment. We know that VRF systems operate efficiently within a very narrow temperature range. For the bulk of the year, both buildings are subject to temperatures far outside rated efficiency conditions, making for larger than expected utility bills.

In the case of a hydronic system, the designer will have specified each component depending upon that specific climate. The building’s energy consumption will be lower, while occupant comfort will be ideal.

Whether you’re looking for the best way to retrofit a 100-year-old apartment complex, or to build a Net Zero high-rise, look to a hydronic system as the leading option.

When it comes to efficiency, water always wins. Think hydronic.

For more information, please contact the Radiant Professionals Alliance and the Hydronics Industry Alliance at (877) 427-6601 or info@HIA-C.org